By Steve Redfield, Class of 2019

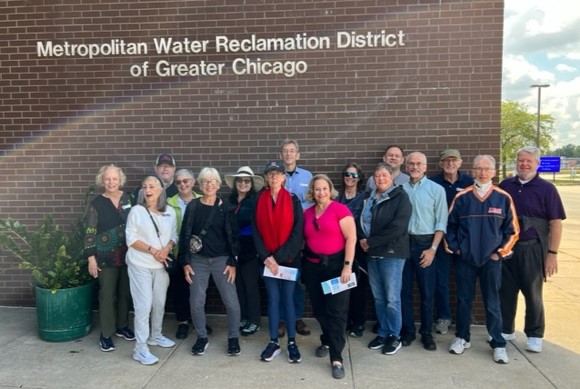

“Don’t talk about what you can’t see,” they tell us. Maybe good advice for tours, but many things we don’t see make our city work. Seventeen volunteers and docents toured a seldom-seen part of our infrastructure, the Metropolitan Water Reclamation District’s (MWRD) Stickney Plant, which has been cleaning Cook County’s wastewater since 1930. The visit was suggested by docent Wayne Galasek, sponsored by our Enrichment Committee, and organized by Barbara Foley. Mike Salerno, MWRD Treatment Plant Operator, was our guide for the two-hour visit.

First placed in service in 1930 and later expanded in 1939, the MWRD’s Stickney Plant stretches over 500 acres and is run by nearly 500 employees. The plant runs 24 hours a day to clean water from Cook County’s combined sanitary sewage and stormwater run-off sewers. It’s one of the largest reclamation plants in the world, able to clean 1.4 billion gallons of water a day. Combined with the six smaller plants that also serve Cook County, Chicago’s MWRD has the total capacity to treat more than 2 billion gallons every day. (Mike reminded us that this system is separate from the City’s process to provide drinking water from Lake Michigan.)

The story of how our water system works was mostly new to us. (Well, there was the moment when Mike asked if we knew that the flow of the Chicago River had been reversed. So at least we had that one in hand.) Stickney combines mechanics and biology, and with rare exceptions, no chemicals to treat and clean our wastewater.

It all begins when the water arrives at the plant, where coarse screens remove large objects such as trash, wood, and yes, sometimes even bowling balls and mattresses. All of that material is destined for landfill. The next step lifts the water to the highest level of the facility with pumps and blowers original to the plant’s 1939 expansion. This equipment was first run by coal, then it was gas, and today it’s run by electricity. No surprise that there’s a full team of tradespeople on staff to keep all of this in good repair. (Incidentally, the valves, gates, shutoffs, etc., throughout the plant are operated manually – they aren’t computerized – in order to avoid the potential of a catastrophic electronic error.)

The rest is literally downhill from there. Once brought to the surface, the water passes through air-driven agitation tanks where sand and other nonorganic debris settle and are drawn off. In the next set of tanks, grease and oils rise to the top, once again headed to landfill, and organic waste settles to the bottom. The organic solids are removed and transported around the facility on 25 miles of MWRD’s own train tracks. It is dried, put through a process similar to composting, and turned into fertilizer for places like golf courses and highway shoulders.

The increasingly clean water is sent to aeration tanks where a combination of microorganisms breakdown the rest of the suspended organic waste, also heading to the fertilizer supply. Finally, in 96 finishing tanks, the last of the waste sinks to the bottom, clean water drips over the top, and empties into the Sanitary and Ship Canal.

All of this is completed in just eight hours, and there is just one small section of the whole plant that has a suggestion of bad odors!

So, with a system that’s approaching 100 years old, what has changed and what’s coming?

- First, the reclamation plants are only a portion of the sewage system. They are supplemented by the Tunnel and Reservoir Plan (TARP), a vast holding system that retains runoff from big storms until it can be cleaned. (If you haven’t noticed them, look for TARP drop shaft grates along the Riverwalk.) That should be completed by 2029. But begun in 1975, it seems unlikely to have sufficient capacity to cope with the more frequent large storms resulting from climate change. So MWRD is now promoting “green infrastructure” that can absorb more rainwater and reduce runoff.

- A recent partnership with a private company converts phosphorous byproducts into a new form of farm fertilizer, activated in the fields by plants, with no harmful water runoff.

- A new contaminant has become a concern in recent years, manmade chemicals known as PFAS. Often referred to as “forever chemicals,” PFAS are nearly indestructible and inevitably remain in Stickney’s processed organic waste. This has led MWRD to stop distributing their fertilizer for home and agricultural use. Microbiologists on staff are researching safe options for using the fertilizer.

- The plant already uses methane extracted by the system to heat all of the facilities. Now they’re working to use it for cooling as well. They are working to be energy neutral by 2030.

Our brains were stretched to capacity with all of this information, but we left with a new appreciation for what it takes to keep our city and environment healthy.

CLICK HERE for more stories on The Bridge.

Thanks, Steve, for this concise and informative review of what you learned. Very helpful for those of us who couldn’t make it in person.

Nice reporting, Steve. It was a very interesting tour. So glad Wayne suggested it. Thanks so much to Barbara for organizing the trip.

Thanks for the complete summary of our interesting morning, Steve!

Great article, thanks Steve

Thanks for your descriptive write-up, Steve! The PFAS aspect about MWRD discontinuing distribution of their fertilizer for home and agricultural use, is particularly interesting.

For those like me who missed the live tour, there is an excellent virtual tour ~1 hr long, on Youtube, albeit from a few years ago: MWRD Virtual Tour: Deep Tunnel, Wastewater Treatment, Green Infrastructure, Chicago Water History. https://www.youtube.com/watch?v=__yXMrBYek4

Thanks Steve for an informative article! Sorry we missed the trip.

This was a really interesting trip – thanks Steve for writing it up, Barbara and Enrichment for making it happen, and Wayne for the suggestion!

I’ve been talking to a lot more people about waste water in the past couple of weeks than I would have anticipated!

In fact last week in NYC I was talking to a client in the insurance industry who confirmed Chicago has the best water mgmt system in the country, while Houston has the worst – too many parking lots down there no where for the water to go so much more flooding!